What We Do

Welcome To The Best Industrial Center Around The World

What We DO

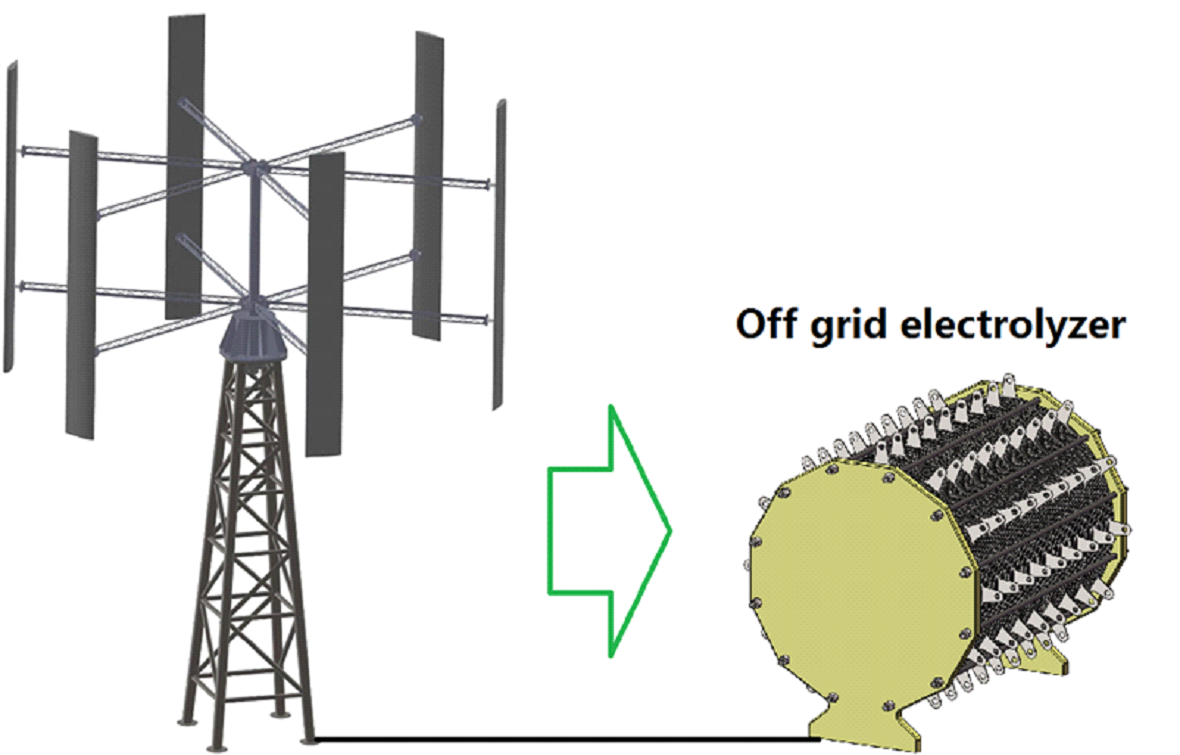

We use grid independent electrolyser tech to set up small distributed hydrogen production/refueling station. Grid independent electrolyser tech can disconnect the grid power to produce hydrogen from water. The power grid can be selected according the electricity price or not. In our electrolyser, each electrode can be controlled by cutting in/cutting off in series connecting according to the power changing from wind/solar. In our hydrogen production station, each electrolyser can be controlled by cutting in/cutting off in parallel connecting according to the power changing from wind/solar.

The grid independent electrolyser can be used as distributed hydrogen production both in small hydrogen production/refueling station and large scale hydrogen production station. Their customers and sales model are different. For small grid independent hydrogen production/refueling station, the customers

are the users or manufactures of hydrogen vehicle. The customers are sensitive in convenience, availability. One station can support (5-10) hydrogen vehicles sales. It will be a most important successful factor of hydrogen vehicle sales. The hydrogen vehicle manufacturer can announce to their customers, no matter where you live, you can find out a hydrogen production/refueling station within

five kilometers. Micro Hydrogen will set up APP for the small grid independent hydrogen production/refueling station. The users can find out where there is a nearest hydrogen refueling station. It is not only a good product, but also is a great investment tool for many people. Another product is large scale hydrogen production station which used in wind farm or solar power station which can reduce at least 50% cost of green hydrogen production. The customers are sensitive in hydrogen production cost.

Our History

In our electrolysis system, either the electrolysers can independent use wind/solar power to hydrogen production, or connect the grid at night to hydrogen production at same time. It can choose according to balance the cost and production output.

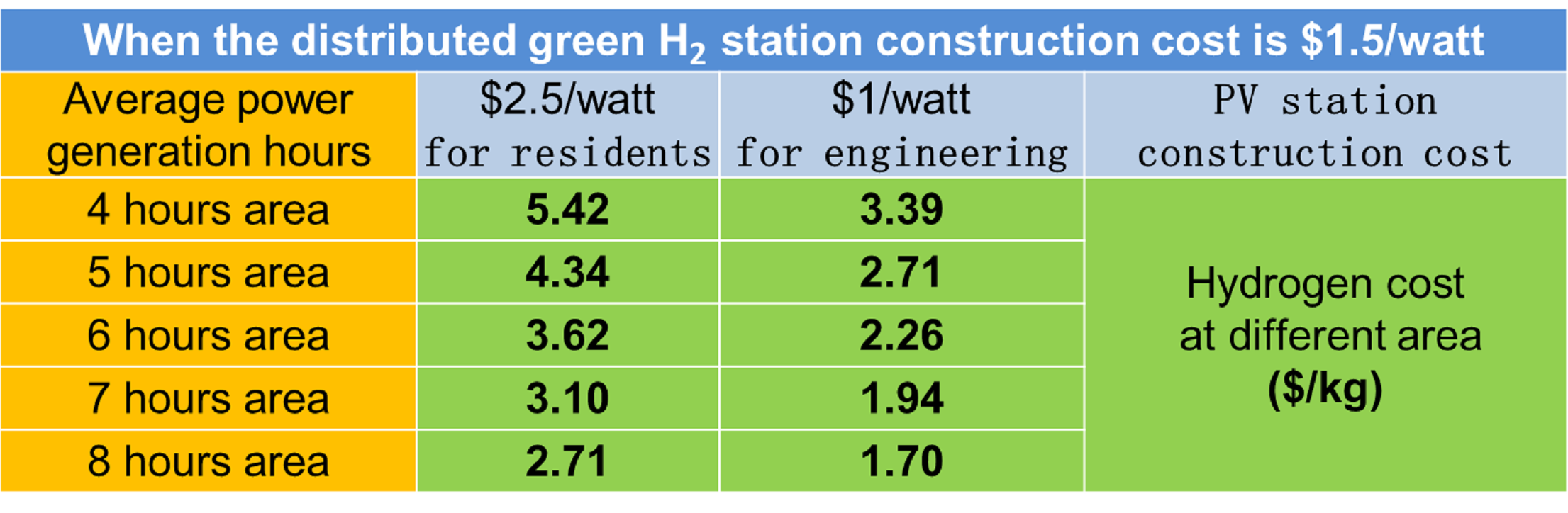

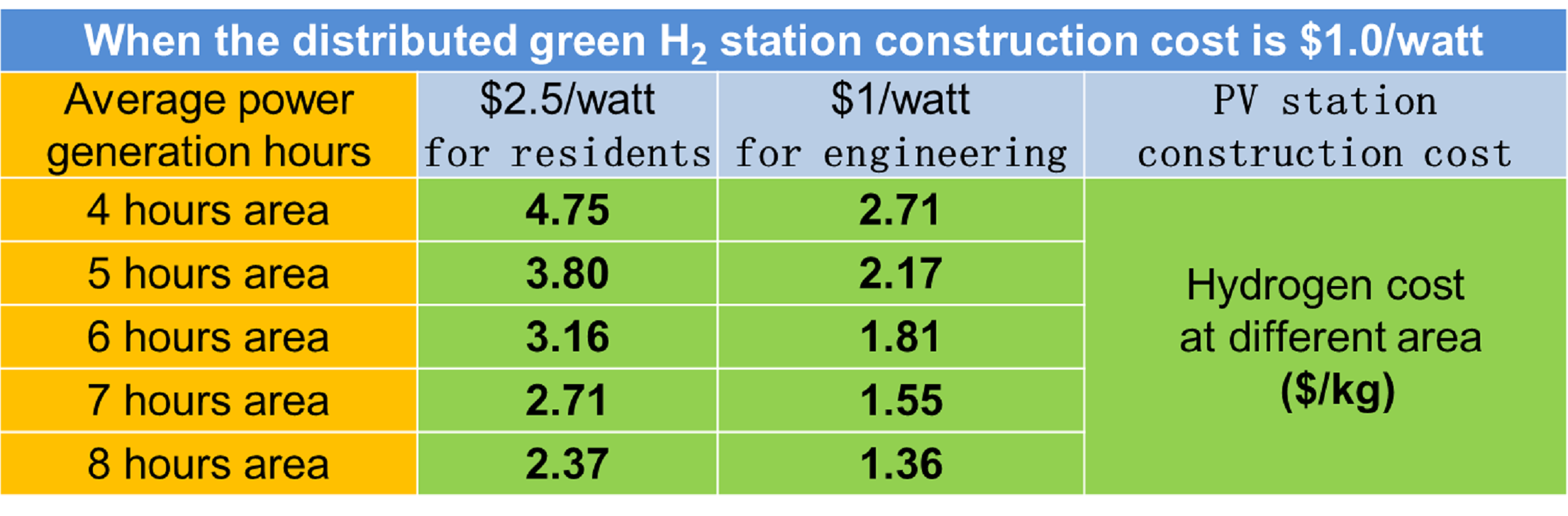

The higher the proportion of hydrogen production use wind power/solar power, the lower the cost of green hydrogen production. The cost of purchasing electricity from grid is always higher than the price of selling the electricity to grid.

Although existing PEM electrolyzer can adapt to larger power fluctuations, such as the power can fluctuate from 20% to 110%, but it mainly adapts to current changes and is not the voltage, the adaptability to voltage fluctuations range is still similar with the traditional electrolysis around 50%. Whether the wind or solar power, the power changes are all caused by voltage changes, the voltage changing range at least 8 times. Existing PEM electrolysis can use wind or solar power for hydrogen production which still needs to be connected to the grid to keep the relatively stable voltage fluctuations. The proportion of wind/solar power is still not high, and grid electricity is still used to hydrogen production at most of time. The cost reduction of green hydrogen is limited.

Our innovation method of green hydrogen is grid independent hydrogen production. In our electrolysers, each electrode and electrolyser can be controlled by cutting in/cutting off according to the power changed from wind and solar power. It can minimize the hydrogen production cost of green hydrogen. But it also can use the grid power to hydrogen production at night which uses hybrid power to hydrogen production.

Our Work

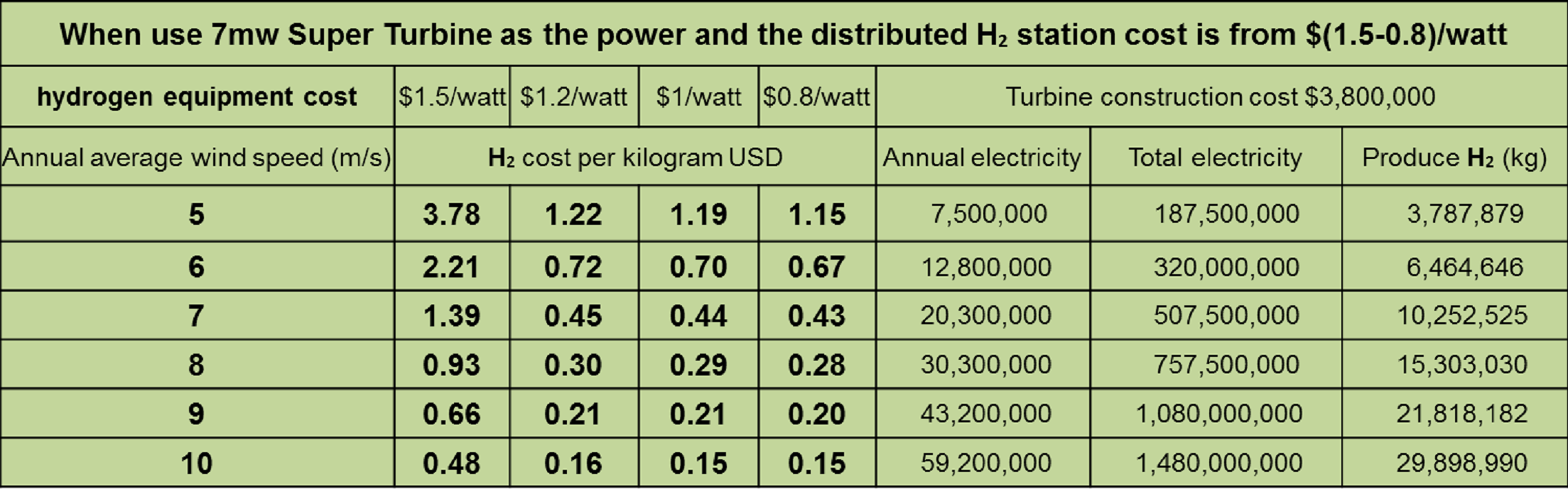

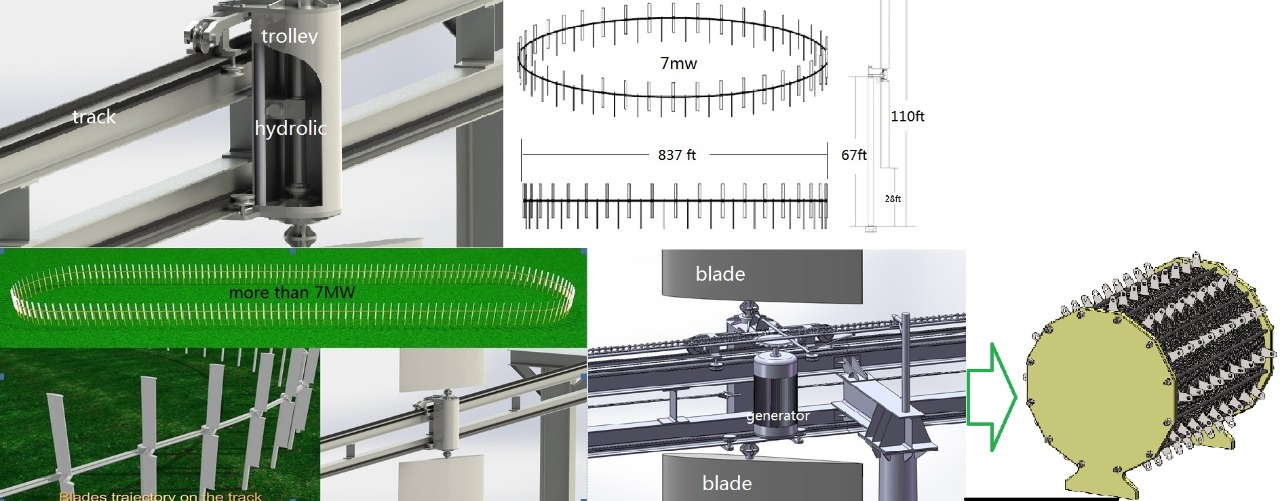

Use 7mw Super Turbine to hydrogen production

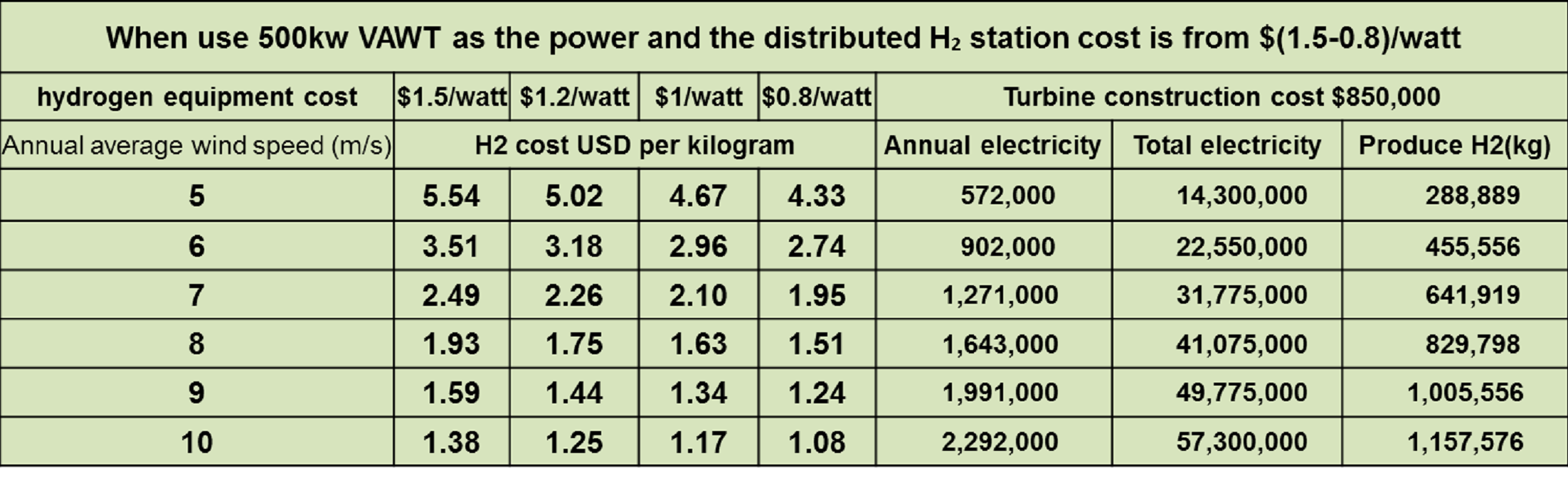

Use 500kw VAWT to hydrogen production

Use solar to hydrogen production