What We Do

Welcome To The Best Industrial Center Around The World

What We DO

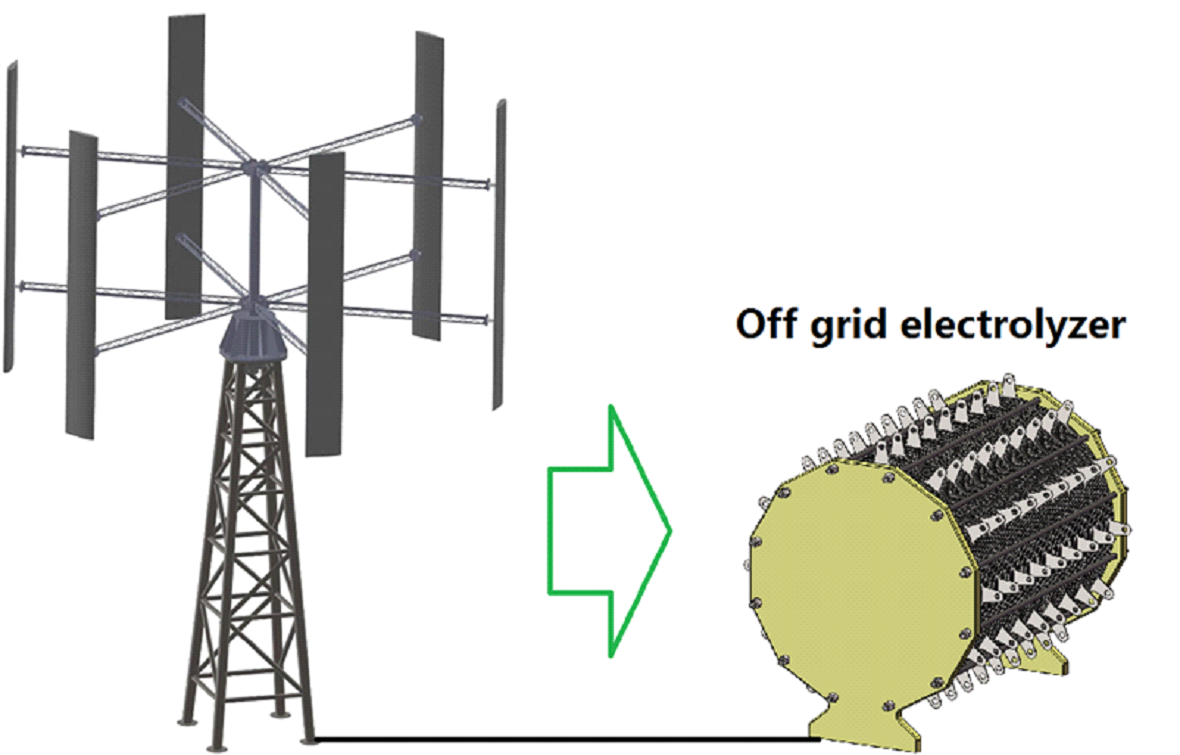

We use grid-independent electrolyzer tech to set up small distributed hydrogen production/refueling stations. Grid-independent electrolyzer tech can disconnect the grid power to produce hydrogen from water. The power grid can be selected according to the electricity price or not. In our electrolyzer, each electrode can be controlled by cutting in/cutting off in series connecting according to the power changing from wind/solar. In our hydrogen production station, each electrolyzer can be controlled by cutting in/cutting off in parallel connecting according to the power changing from wind/solar.

The grid-independent electrolyzer can be used as distributed hydrogen production both in small hydrogen production/refueling stations and large-scale hydrogen production stations. Their customers and sales models are different. For small grid-independent hydrogen production/refueling stations, the customers

are the users or manufacturers of hydrogen vehicles. Customers are sensitive to convenience and availability. One station can support (5-10) hydrogen homes using vehicle sales. It will be a most important successful factor in hydrogen vehicle sales. The hydrogen vehicle manufacturer can announce to their customers, that no matter where you live, you can find a hydrogen production/refueling station within five kilometers. Micro Hydrogen will set up an APP for the small grid-independent hydrogen production/refueling station. The users can find out where there is a nearest hydrogen refueling station. It is not only a good product but also a great investment tool for many people.

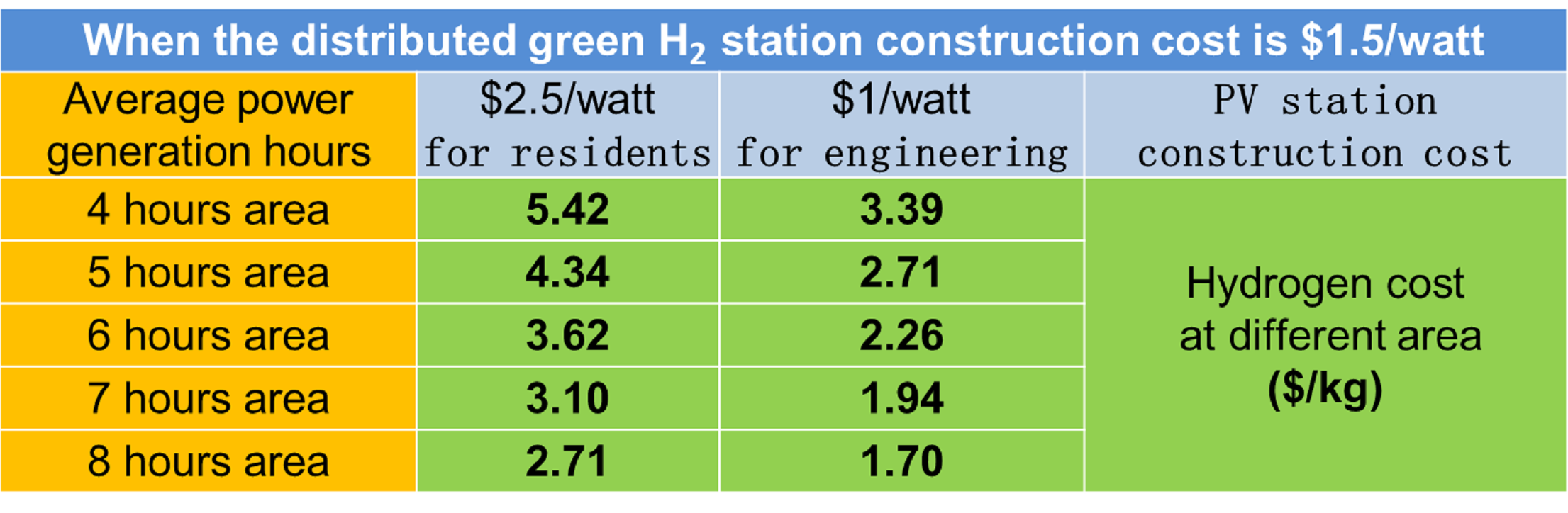

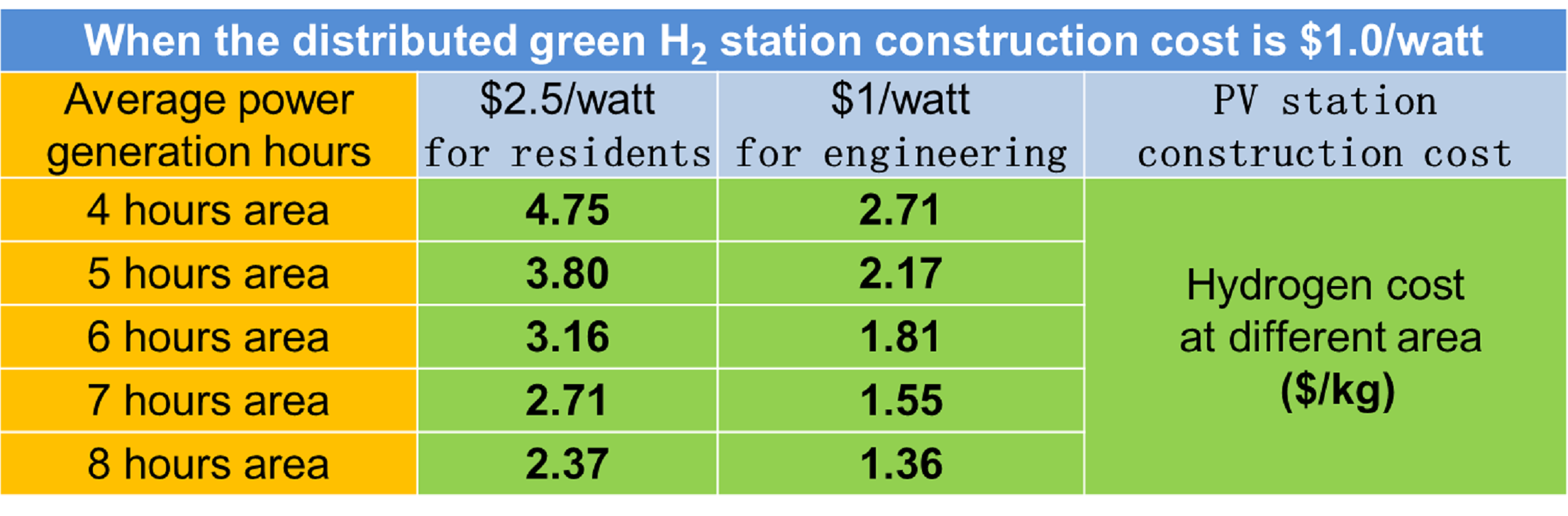

Another product is large-scale hydrogen production stations used in wind farms or solar power stations, which can reduce at least 50% of the cost of green hydrogen production. Customers are sensitive to hydrogen production costs.

Our History

As an energy carrier, hydrogen is positioned to address dwindling fossil energy and increasing environmental issues. Both wind and solar are desirable renewable energy sources to produce green hydrogen, but they are unsteady and intermittent in nature. Due to electrochemical principles, a narrow range of stack voltage is required for efficient and safe operation in the electrolysis, subject to the stack configuration. The varying voltage from wind/solar power poses a technical challenge for practical integration between renewable energy and hydrogen production. Adopting voltage-variable transformers could solve this mismatch problem. Unfortunately, the concurrent practice is to discard renewable power when the voltage is lower than the electrolysis rating, which results in a substantial waste of energy. If designing the lower-rated voltage for an electrolysis system, it risks abandoning more renewable power when the voltage is higher than the rating. Another common practice is supplementing grid power with wind/solar power to produce hydrogen, which only increases costs. Clearly, the dilemma between the varying voltage power from renewable energy and the narrow voltage rating of electrolysis systems is calling for a game-changing solution.

Micro Hydrogen’s “voltage-adaptable electrolysis” is based on a smart electrode regulation technology, which works similarly to voltage-variable transformers but is fundamentally different. Our voltage management technology is of “voltage adaptation,” as opposed to the “voltage alternation” in all transformers. The voltage adaptation is achieved by our design of a series of subunits.

Essentially, our concept transfers the formidable electrolysis challenge into a more solvable electrical control problem, in accommodation to the unsteady renewable power sources. Our solution could halve the production cost of green hydrogen, compared with existing technology powered by solar/wind energy.

Our solution was proved by a 600-watt grid-independent electrolyzer with 14 electrodes. If successful in a real product, our solution could assist the USA in achieving and even accelerating the 2030 long-term strategy of clean hydrogen costs of $1/kg.

Our Work

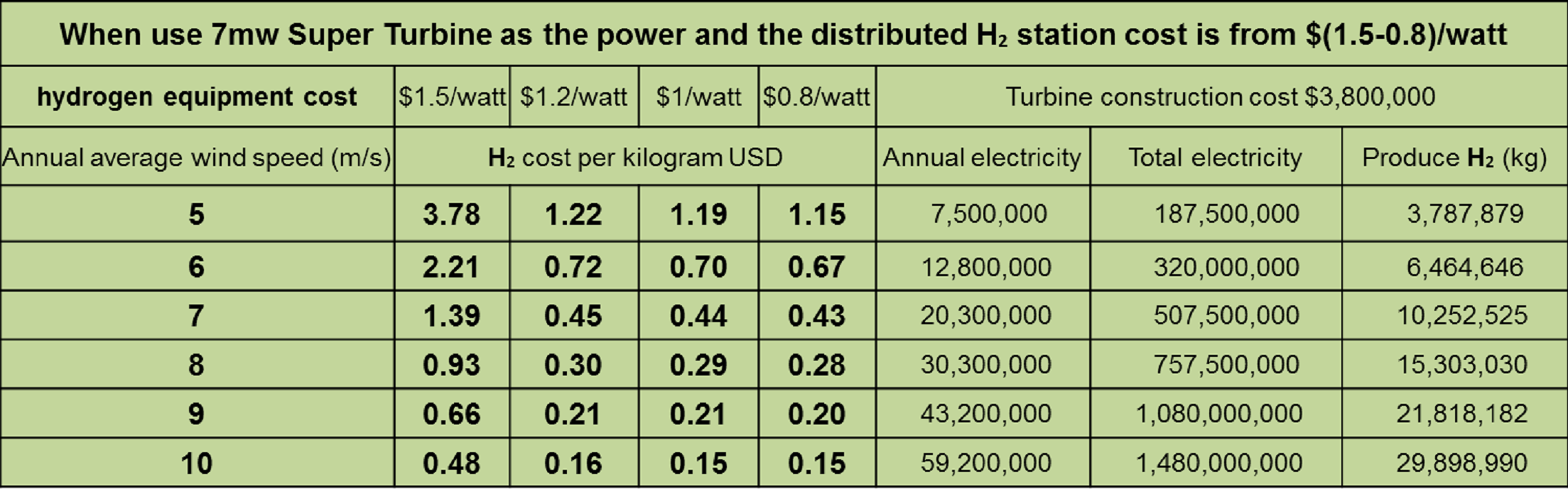

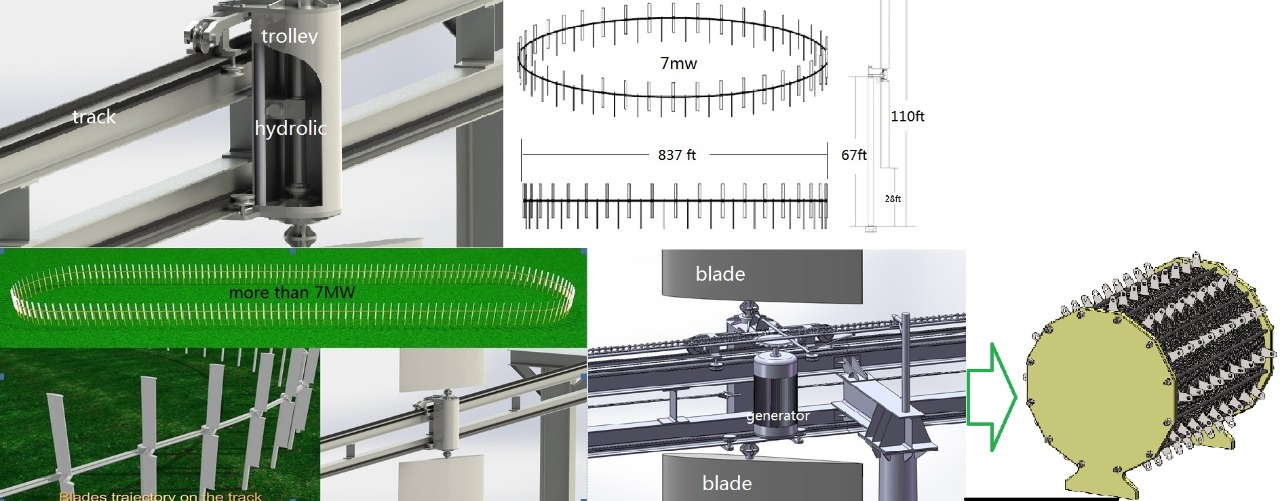

Use 7mw Super Turbine to hydrogen production

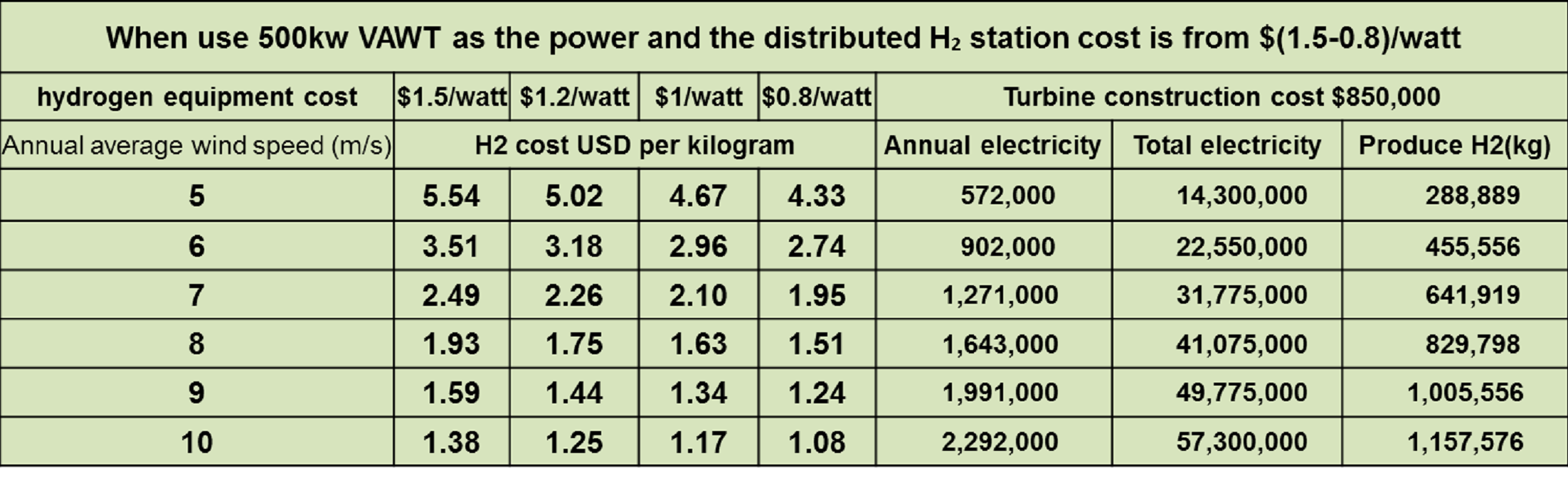

Use 500kw VAWT to hydrogen production

Use solar to hydrogen production